How Parma Ham is made

The haunches of pork from pigs born, bred and slaughtered in the regions laid down in the regulations of the Consortium of Parma Prosciutto (Emilia Romagna, Lombardy, Piedmont, the Veneto, Tuscany, Umbria, the Marches, Abruzzo, Lazio and Molise) and coming from certified slaughter houses, after an accurate selection process carried out by specialist workers from the company in collaboration with inspectors from the Consortium, are identified by means of a metal tag which indicates the month and year when production begins.

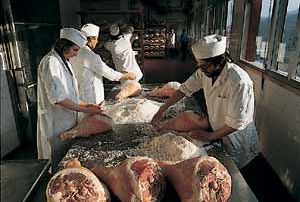

With knowledgeable but careful gestures the master salters sprinkle a moderate quantity of salt onto the rind and the unprotected muscle surface of the haunch, and then place them in refrigerated rooms where they rest for between 20-25 days. At the end of this period, the residual salt is removed and the hams are transferred to another ‘resting’ room for a further 70-80 days.

After the salt has uniformly distributed itself within the muscular mass, the prosciutti are washed down with luke-warm water to remove eventual residual salt and impurities and are then dried in a temperature controlled environment. In this way the phase of pre-maturing begins with the hams hung on the traditional ‘scalera’ or racks in large rooms with high windows on either side to favour optimum ventilation.

The sealing process or “Sugnatura”

After the long months of rest, the hams are beaten with wooden bats to accentuate the typical rounded shape. Then the operation of sealing or ‘sugnatura’ takes place: the muscle areas of the ham which are not protected by rind are covered with ‘sugna’ which is a paste of pork fat minced up with salt and ground pepper. This treatment aims to soften the outside layers and avoid an over rapid drying process with respect to the inside of the ham.

The prepared hams are now ready to conclude the maturing process in cool, moderately ventilated rooms: the ‘cellars’. At the end of the maturing period which is never less than 10 months for hams which weigh between 7-9 kg and 12 months for those which weigh more, the prosciutto has lost most of its initial weight.

The Consortium, having already carried out rigorous checks in all the phases from breeding to butchering and then from tagging to maturing, now proceeds to particular controls using a body of its own inspectors who test the prosciutti with the method known as ‘puntatura’ which allows them to be given a definitive quality appraisal and judgement.

At the end of the correct maturing period, the hams are tested by the Inspectors who, using a needle made from the bone of a horse which has particular characteristics, make minute holes between the muscle and the rind of the prosciutto in 5 different places and examine the aroma of the product which is a guarantee of uniform and perfect maturity. Only those prosciutti which pass this test proving that they have matured in an optimal way can become Parma Prosciutti and receive the Consortium mark.

Branding

At this point the prosciutti are ready to be officially recognised: fire branding with the mark of the 5 pointed Ducal Crown of the Consortium of Parma Prosciutti. Since 1991, furthermore, the mark also includes the initials of the production plant, making certain and unequivocable the provenance of each single prosciutto.

The prosciutto is now ready for distribution and marketing and so it arrives on our tables where slice after slice it will liberate its unmistakeable aroma, its delicate but unique flavour, the true taste of Parma ham.

The ancient processing of Parma Ham

De-boned and vacuum packed, Parma ham can be kept for up to 6 months in a correctly cooled environment at between 4 and 8° C.

Attention:

Only Parma Prosciutto on the bone can be hung up. In this case it can be kept for longer: for up to 12 months in an environment at between 17 and 20°.

Once opened, the ham can be kept in the fridge for a month, as long as the cut part is covered with cling-film and the whole ham is wrapped in a cotton cloth.